In today’s manufacturing industry, precision and efficiency are key factors in ensuring the success of a business. Advanced CNC metal cutting techniques have revolutionized the way metal components are produced, allowing for greater accuracy, faster production times, and cost savings. By implementing these cutting-edge technologies, companies can optimize their production processes and stay ahead of the competition.

Introduction to CNC Metal Cutting

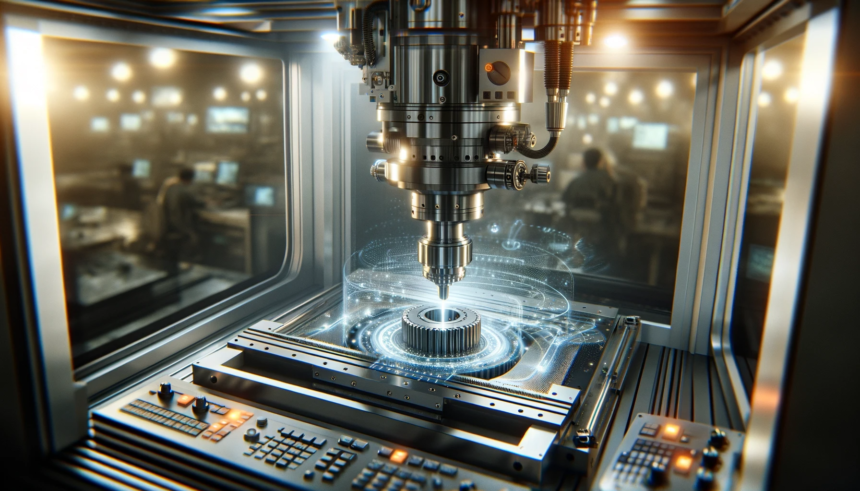

CNC (Computer Numerical Control) metal cutting involves the use of computer-controlled machines to remove material from a workpiece. This process is highly precise and can be used to create complex shapes and designs with ease. Traditional metal cutting methods, such as manual milling and turning, are not as efficient or accurate as CNC machining.

Benefits of Advanced CNC Metal Cutting Techniques

There are several benefits to using advanced CNC metal cutting techniques in the manufacturing industry. One of the primary advantages is the ability to produce parts with incredibly tight tolerances. CNC machines can repeatedly create parts with high precision, ensuring consistency and quality in every piece produced.

Increased Efficiency and Productivity

Advanced CNC metal cutting techniques also lead to increased efficiency and productivity in the production process. These machines can operate continuously, 24/7, with minimal human intervention. This results in faster production times and higher output rates, allowing companies to meet tight deadlines and customer demands.

Cost Savings

Implementing advanced CNC metal cutting techniques can also result in significant cost savings for companies. While the initial investment in CNC machines may be high, the long-term benefits far outweigh the costs. By reducing the need for manual labor and minimizing material waste, CNC machining can help companies lower their production costs and improve their bottom line.

Improved Safety

Another advantage of using advanced CNC metal cutting techniques is improved safety in the workplace. CNC machines are equipped with various safety features, such as automatic tool changers and collision detection systems, to prevent accidents and injuries. This creates a safer working environment for employees and reduces the risk of costly downtime due to accidents.

Enhanced Quality Control

Quality control is crucial in the manufacturing industry to ensure that products meet the required specifications and standards. Advanced CNC metal cutting techniques enable companies to maintain strict quality control measures throughout the production process. With CNC machines, companies can perform in-process inspections and make real-time adjustments to ensure the final products meet the desired quality standards.

Applications of Advanced CNC Metal Cutting Techniques

Advanced CNC metal cutting techniques are used in a wide range of industries, including aerospace, automotive, electronics, and medical device manufacturing. These techniques are ideal for producing complex parts and components that require high precision and accuracy. From prototyping to mass production, CNC machining offers versatility and reliability in producing a variety of metal components.

Future Trends in CNC Metal Cutting

As technology continues to advance, the future of CNC metal cutting looks promising. Innovations such as 5-axis machining, robotic automation, and AI-driven programming are transforming the way metal components are manufactured. These advancements will further enhance the precision, efficiency, and capabilities of CNC machines, allowing companies to stay competitive in a rapidly evolving market.

Conclusion

Optimizing production with advanced CNC metal cutting techniques is essential for companies looking to improve efficiency, quality, and profitability. By leveraging the power of CNC machining, businesses can streamline their production processes, reduce costs, and stay ahead of the competition. Investing in advanced CNC metal cutting technologies is not only a strategic decision but a necessary one to thrive in today’s fast-paced manufacturing industry.