In today’s competitive business environment, staying ahead of the curve is essential for success. Rapid prototyping has revolutionized the way products are developed and brought to market. It allows businesses to quickly create prototypes of their products, test them, and make necessary iterations before final production.

Choosing the right rapid prototyping machine for your business is a crucial decision that can have a significant impact on your product development process. In this article, we will discuss the factors you need to consider when selecting a rapid prototyping machine that best suits your business needs.

Understanding Your Business Requirements

The first step in choosing the right rapid prototyping machine is to understand your business requirements. Consider the size of your prototypes, the materials you will be using, the level of detail required, and the volume of prototypes you need to produce.

Different rapid prototyping technologies offer various capabilities, so it’s essential to align your business requirements with the features of the machine.

Types of Rapid Prototyping Technologies

There are several rapid prototyping technologies available in the market, each with its unique advantages and limitations.

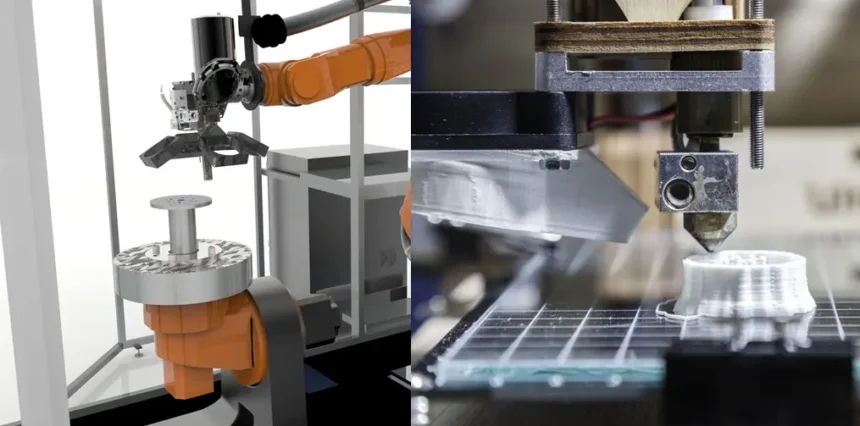

A rapid prototyping machine quickly and efficiently creates physical models from digital designs, allowing real-time testing and refinement by designers and engineers. Some of the most common rapid prototyping technologies include:

1. Stereolithography (SLA): SLA uses a laser to solidify layers of resin to create a 3D object. It is known for its high level of detail and accuracy, making it ideal for intricate designs. However, the process can be relatively slow and the materials used can be more expensive.

2. Selective Laser Sintering (SLS): SLS involves using a laser to sinter powdered material, such as plastic or metal, layer by layer to build a prototype. It is a versatile technology that can work with a variety of materials, but the surface finish may not be as smooth compared to other methods.

3. Fused Deposition Modeling (FDM): FDM is a popular choice for rapid prototyping due to its speed and cost-effectiveness. It works by extruding thermoplastic materials to build up the prototype layer by layer. While FDM is great for producing functional prototypes, it may not offer the same level of detail as other technologies.

4. Digital Light Processing (DLP): DLP is similar to SLA, but instead of using a laser, it uses a projector to cure each layer of resin. DLP is known for its speed and ability to produce accurate prototypes. However, the materials used in DLP can be more limited compared to other technologies.

5. Binder Jetting: Binder jetting involves depositing layers of powder material and using a liquid binder to bind the particles together. This technology is fast and cost-effective, making it suitable for producing prototypes in a short amount of time. However, the prototypes may not have the same strength as those produced using other methods.

These are just a few examples of rapid prototyping technologies available in the market, each offering unique benefits and considerations depending on the specific requirements of the project.

Considerations for Choosing a Rapid Prototyping Machine

When selecting a rapid prototyping machine for your business, there are several key considerations to keep in mind:

1. Technology: Consider the type of technology used by the rapid prototyping machine. Common technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). Choose a technology that best suits your prototyping needs.

2. Speed and Accuracy: Evaluate the speed and accuracy of the machine. Faster machines can produce prototypes quickly, while machines with higher accuracy can create more detailed and precise prototypes.

3. Build Volume: Consider the build volume of the machine, which determines the size of the prototypes that can be produced. Choose a machine with a build volume that meets your project requirements.

4. Material Compatibility: Check the range of materials that the machine can work with. Different rapid prototyping machines support different types of materials, such as plastics, metals, or ceramics. Make sure the machine can use the materials you need for your prototypes.

5. Ease of Use: Look for a machine that is user-friendly and easy to operate. Consider factors such as software interface, maintenance requirements, and technical support available from the manufacturer.

6. Cost: Determine the initial cost of the machine as well as ongoing operational costs such as material expenses and maintenance. Choose a machine that fits within your budget and offers good value for the price.

7. Additional Features: Consider any additional features or capabilities offered by the machine, such as multi-material printing, high-resolution printing, or support for complex geometries. These features can enhance the versatility and functionality of the machine.

8. Manufacturer Reputation: Research the reputation of the manufacturer of the rapid prototyping machine. Choose a reliable and reputable manufacturer with a track record of producing high-quality machines and providing excellent customer support.

By carefully considering these key factors, you can select a rapid prototyping machine that best meets the needs of your business and helps you create high-quality prototypes efficiently.

Choosing a Reliable Supplier

Once you have identified your business requirements and the type of rapid prototyping technology that best suits your needs, the next step is to choose a reliable supplier. Look for a supplier with a proven track record of delivering high-quality machines and excellent customer support. Consider factors such as warranty, training, and technical assistance when selecting a supplier for your rapid prototyping machine.

It is essential to choose a supplier that offers a warranty on their machines to protect your investment. Additionally, ensure that the supplier provides comprehensive training on how to use the rapid prototyping technology effectively. Technical assistance is also crucial, as you may encounter issues or have questions while using the machine. A reliable supplier will offer ongoing support to help you maximize the benefits of rapid prototyping for your business. Conduct thorough research, read reviews, and ask for recommendations to find a reputable supplier that meets your requirements and can provide the necessary support for your rapid prototyping needs.

Training and Support

Proper training and ongoing support are essential for maximizing the potential of your rapid prototyping machine. Ensure that your team receives adequate training on how to operate the machine safely and efficiently. Additionally, choose a supplier that offers reliable technical support to address any issues or challenges that may arise during the prototyping process.

Proper training and ongoing support are essential for maximizing the potential of your rapid prototyping machine. It is crucial to ensure that your team receives adequate training on how to operate the machine safely and efficiently. This will not only help in enhancing productivity but also prevent accidents or damage to the equipment.

Conclusion

Choosing the right rapid prototyping machine for your business is a critical decision that can impact your product development process significantly. By understanding your business requirements, exploring different rapid prototyping technologies, considering key factors such as accuracy, speed, material compatibility, and cost, and selecting a reliable supplier, you can make an informed decision that aligns with your business goals. Investing in the right rapid prototyping machine can enhance your product development capabilities, streamline your prototyping process, and ultimately drive innovation and success for your business.